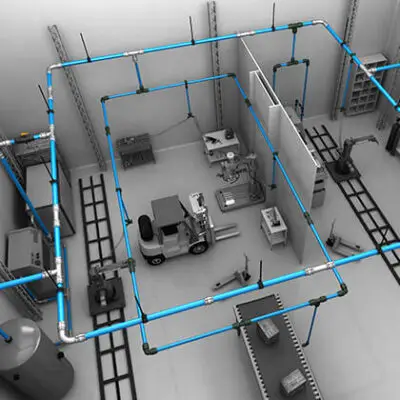

A compressed dry air process piping (CDA) is used to deliver compressed dry air to areas where needed (labs, warehouse, equipment etc.). Compressed dry air is considered essential to production and is used in many commercial / industrial facilities. A poorly designed CDA system can increase energy costs, cause equipment failure, reduce production efficiencies, and increase maintenance requirements.

At WCI, we are committed to help you select and design the most effective compressed air system via process piping for your needs – that includes considering demand, compressed air quality, supply, storage, distribution, installation, maintenance, process piping, and condensate management. We understand how critical it is to keep all of your tools and machines that require compressed air to continuously work efficiently.

Let us know about your project of process piping so we can answer your questions and provide an estimate. You can also use our contact us page to send your query and recommendations to us.

Whether you need a Industrial ELECTRICIAN or commercial ELECTRICIANS you can rely on WCI Electric for quick and efficient solutions at cost-effective rates.

Address:

3088 El Camino Real Unit 2 Santa Clara, CA 95051

Teliphone:

(408) 242 2069

Email:

info@wcielectric.com